Research team develops new interface for silicon germanium semiconductor devices.

Computer chips made of silicon form the backbone of information technology, but in view of ever increasing miniaturization and ever higher performance, the semiconductor material is reaching its limits. This is where gallium nitride (GaN) comes on the scene as a successor, for example in the chips for 5G wireless technology, which show no loss of performance despite high temperatures.

Scientists at the Vienna University of Technology, in collaboration with research teams from Linz and Thun in Switzerland, have now shown that silicon should not be written off as a chip material. Their research is based on the compound semiconductor silicon germanium, which has been used for many years but has as yet untapped potential. According to the scientists, this would require increasing the proportion of germanium, which would significantly increase energy efficiency and the achievable clock frequencies. Faster computers or even completely new quantum devices would then be conceivable.

New opportunities for an old acquaintance

But the use of germanium brings with it a problem, because the technology metal, which was the leading semiconductor material until the 1970s, reacts significantly differently than silicon as soon as it comes into contact with oxygen during the manufacturing process. The large number of oxides that can form as a result cause the components to exhibit different electronic properties, explains Masiar Sistani of the Institute for Solid State Electronics at TU Wien. This poses a problem when the material is connected to metallic contacts, because the finished element cannot be relied upon to meet requirements.

The researchers found the solution to the problem in a process presented in the journal Small, which eliminates contamination of the interface between aluminum and silicon germanium. Crucial to this is an intermediate layer of pure silicon and the controlled heating of the structure to around 500 degrees Celsius. Oxygen atoms would not have the opportunity to enter this high-purity interface in the novel process, Sistani added.

The manufacturing process is reproducible and can be used relatively quickly in the chip industry, explains Prof. Walter Weber, head of the Institute for Solid State Electronics. The necessary systems are already available there. The way is thus paved for a variety of next-generation nanoelectronic, optoelectronic and quantum devices.

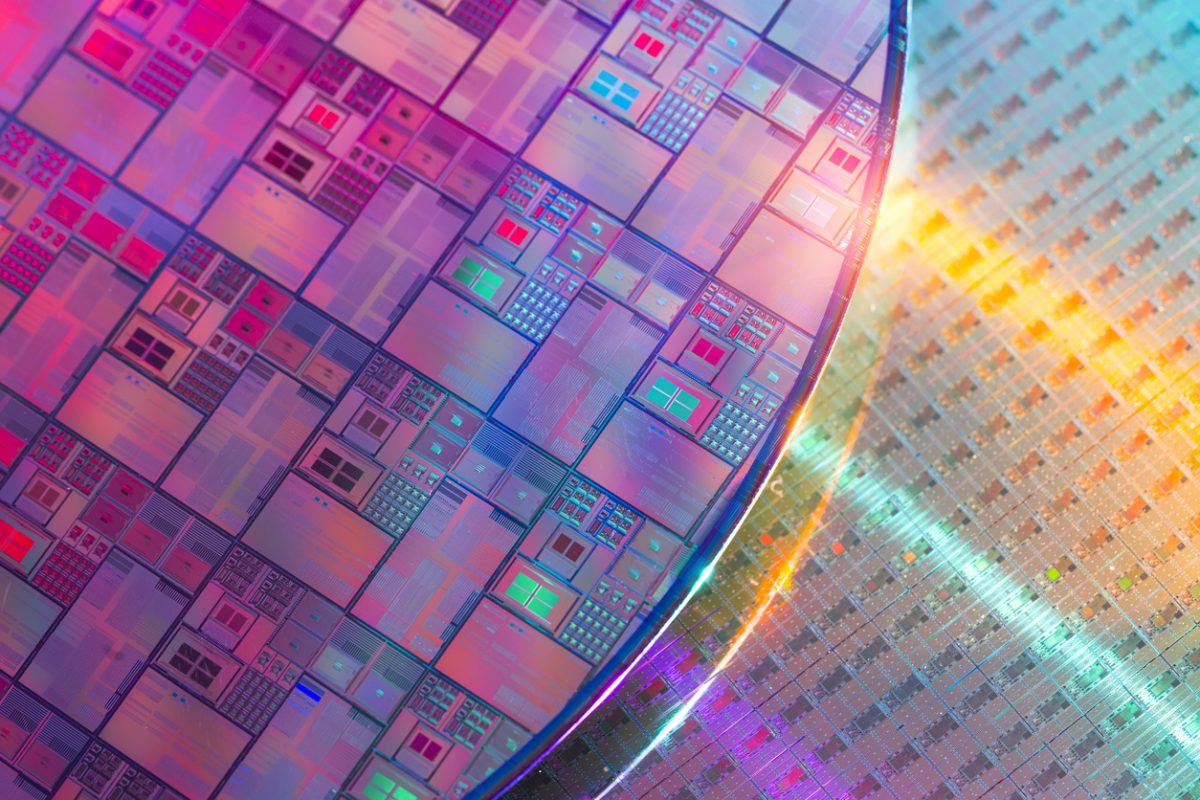

Photo: iStock/kynny