X-ray source based on indium gallium provides new insights into the manufacturing process.

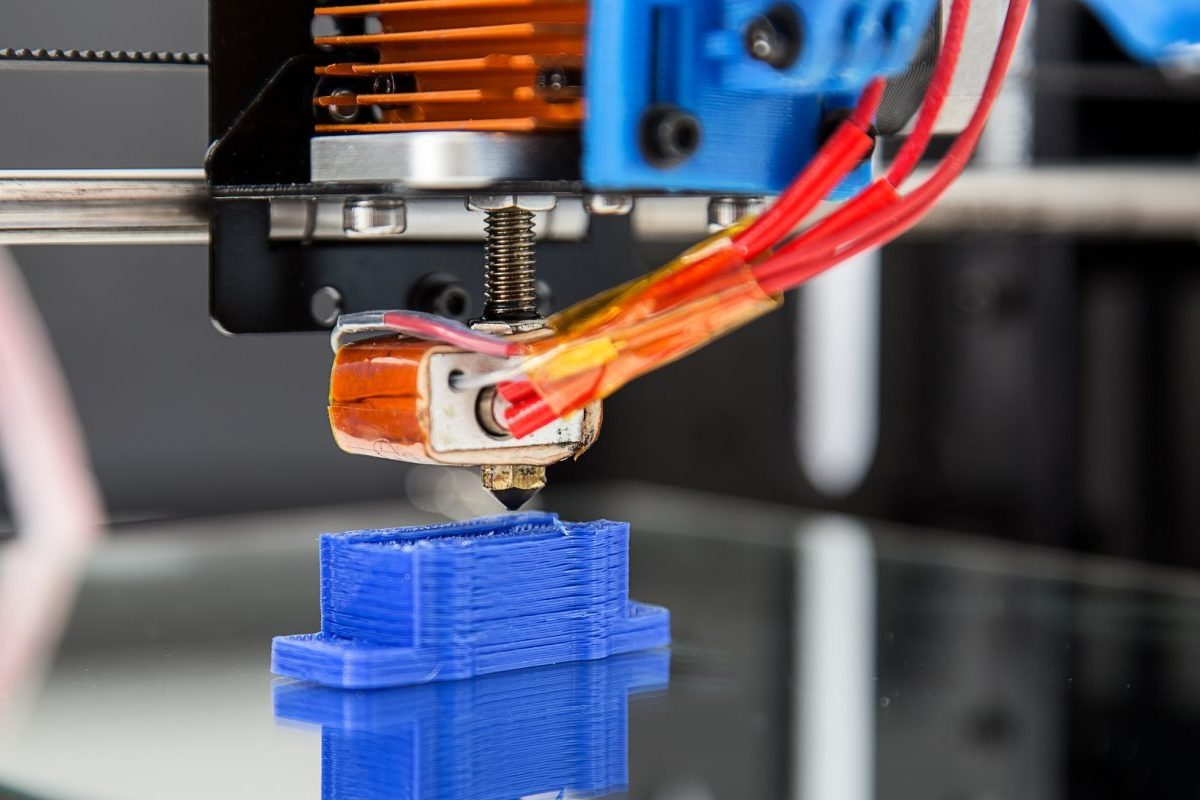

Printing instead of milling: The layer-by-layer production of workpieces made of plastics or other fusible materials has already become established in many industries. At the University of Kassel, work is underway on a process that makes 3D printing of components made of metal visible in real time and down to the atomic level.

At the heart of this facility is the world’s brightest laboratory X-ray source, the university said in a press release. The X-rays from the MetalJet E1+ 160 kV, originate at a liquid anode made of an indium-gallium alloy. This alloy is circulated by a pump that removes the generated heat. The device is the first in its performance class in Europe, the researchers said.

The next step will be to add a 3D printing facility. It will then be possible to observe the printing process in detail and monitor the effect of minute changes in the manufacturing process without delays. This would allow errors to be detected and corrected more quickly. In addition, it would be possible to develop new materials and further optimize printing processes.

Photo: iStock/Alexander Traksel